Our ApproachAbsolute Cutting Tools applies a unique approach to how it designs and develops tools for its customers. Leveraging deep experience in tool design concepts, material selection and process control, our tools consistently deliver impressive results to our customers. How we apply this experience and the benefits you can expect to gain from using our tools, both differentiate Absolute from other tool manufacturers.

Carbide: Absolute uses the best available carbides for its tools. The carbides we use are free of re-grind and feature specifications and compositions that exceed established industry standards and are uniquely suited to the tool applications of our customers.

Tool Design: Absolute's team has decades of combined experience in tool design, manufacturing, and computer controlled technology. Our team constantly keeps current with leading-edge tool design concepts, techniques, methods and materials allows us to constantly extend this breadth of experience and offer our customers unique solutions to their tooling challenges.

Workmanship: Absolute understands the critical need for process consistency and repeatability. We have defined process methodologies expected of our customers with very stringent quality management and quality assurance requirements. Our "no-compromise" approach and attention to detail mean that our customers can be assured of predictable results each and every time with our tools.

Micro-Geometry: The combination of our precision equipment and engineering approach enables us to deliver consistent micro-geometry in our tools. Accuracy of micro-geometry provides a significantly stronger cutting edge, increasing our tool longevity and increasing your production rate.

Coating: Depending on application, Absolute can apply single or multiple coatings to our tools. These coatings have different attributes and characteristics, depending on application, but share the same benefits: bolstering production rates and increasing the longevity of our tools.

Seem too good to be true? That's what we thought when we started developing and manufacturing tools in 2008. Absolute was started with the goal of matching the quality of tools that existed in the market. What we've learnt from our customers since is that the value we deliver to our customers in unrivalled. Instead of matching the quality of other tool manufacturers, our tools have set a new bar for what manufacturers can expect from their tools.

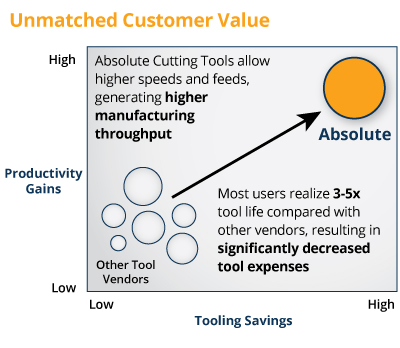

Productivity Gains: Fundamentally our customers share a common business goal - optimizing manufacturing output thereby increasing profitability. Absolute's tools enable your machines to run at higher speeds and feeds. By significantly reducing chatter, our tools enable higher manufacturing throughput.

Tooling Savings: Producing more parts faster is only part of the equation. Value also comes from reducing your tooling expenses. By leveraging Absolute's tools, customers experience an immediate and sustainable saving in tooling expenses. In fact our customers realize an impressive 3-5x tool life compared with other tool vendors; all without a cost premium for this quality level and the fact that our tools are exclusively manufactured here in Montana, USA.

Representative Case Study: A Boeing Fabrication Facility uses a 1x6 4 flute end mill made of 17-4 PH Stainless Steel from Absolute. This tool is used for fabricating commercial airframe flap failsafe bars. The facility performed an internal return-on-investment analysis for this tool, reporting a 5x longevity improvement and a 25% MRR improvement. Translated into financial return, this one tool generated an estimated $5,900 per month savings in productivity improvements and $8,000 per month savings in tool life. See what other customers have said about Absolute Cutting Tools and the value we provide to them.

|